I-Plastic extrusion isetshenziswa kakhulu embonini yepulasitiki yanamuhla ngoba itholakala kalula futhi kulula ukusebenza ngayo.Inqubo ye-plastic extrusion ihilela ukuncibilika kwezinto zepulasitiki, ukuphoqelela ukuba ku-die ukuze kuyibumbe iphrofayili eqhubekayo, bese uyisika ibe ubude.Inqubo iyisinqumo esihle sezinhlelo zokusebenza ezidinga umkhiqizo wokugcina onesiphambano esingaguquki.Izindleko eziphansi kanye namazinga aphezulu okukhiqiza akwenza kube ukukhetha okuvamile kokukhiqiza emikhiqizweni enjengamapayipi, amashidi epulasitiki, ukukhumula isimo sezulu, ukufaka izintambo kanye netheyiphu yokunamathela.

Plastic Extrusion Supplies

Ngaphambi kokuqala inqubo ye-plastic extrusion, kufanele kutholwe imishini efanele kanye nempahla, ikakhulukazi umshini we-plastic extruder.Le divayisi ingumshini olula osiza inqubo yokukhipha kusukela ekuqaleni kuya ekugcineni.Izingxenye eziyinhloko ze-extruder yepulasitiki zifaka i-hopper, umgqomo, i-screw drive kanye ne-screw drive motor.

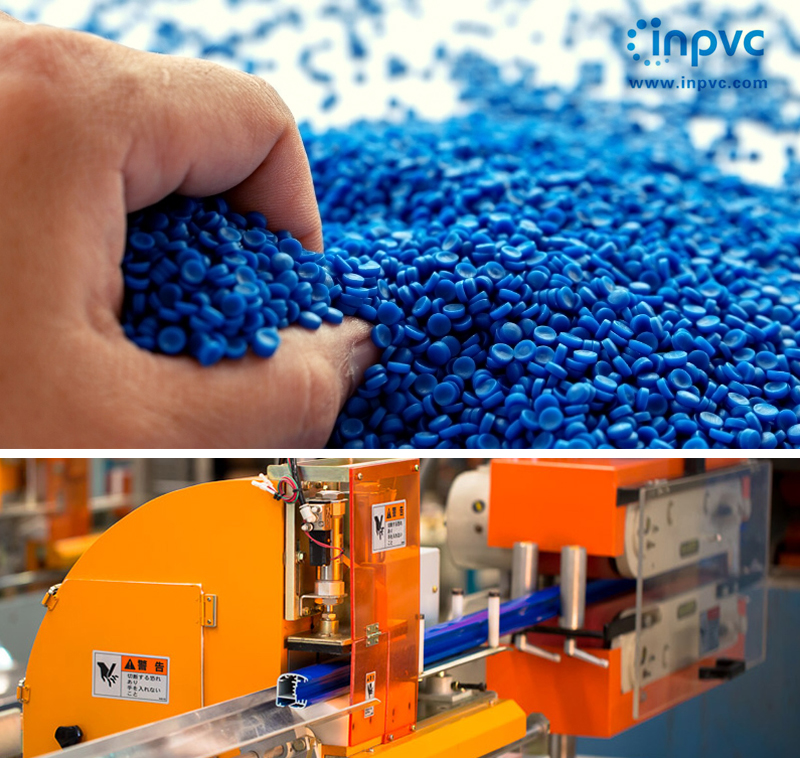

Ingxenye yesibili ebaluleke kakhulu into eluhlaza ye-thermoplastic ehloselwe ukukhishwa.Iningi lemisebenzi ye-extrusion incike kupulasitiki we-resin (ubuhlalu obuqinile obuncane) ukuvumela ukulayisha okulula kanye nezikhathi zokuncibilika ngokushesha.Izinto zepulasitiki ezijwayelekile ezisetshenziswa enqubweni ye-extrusion zihlanganisa i-polystyrene ephezulu (HIPS), i-PVC, i-polyethylene, i-polypropylene, ne-ABS.

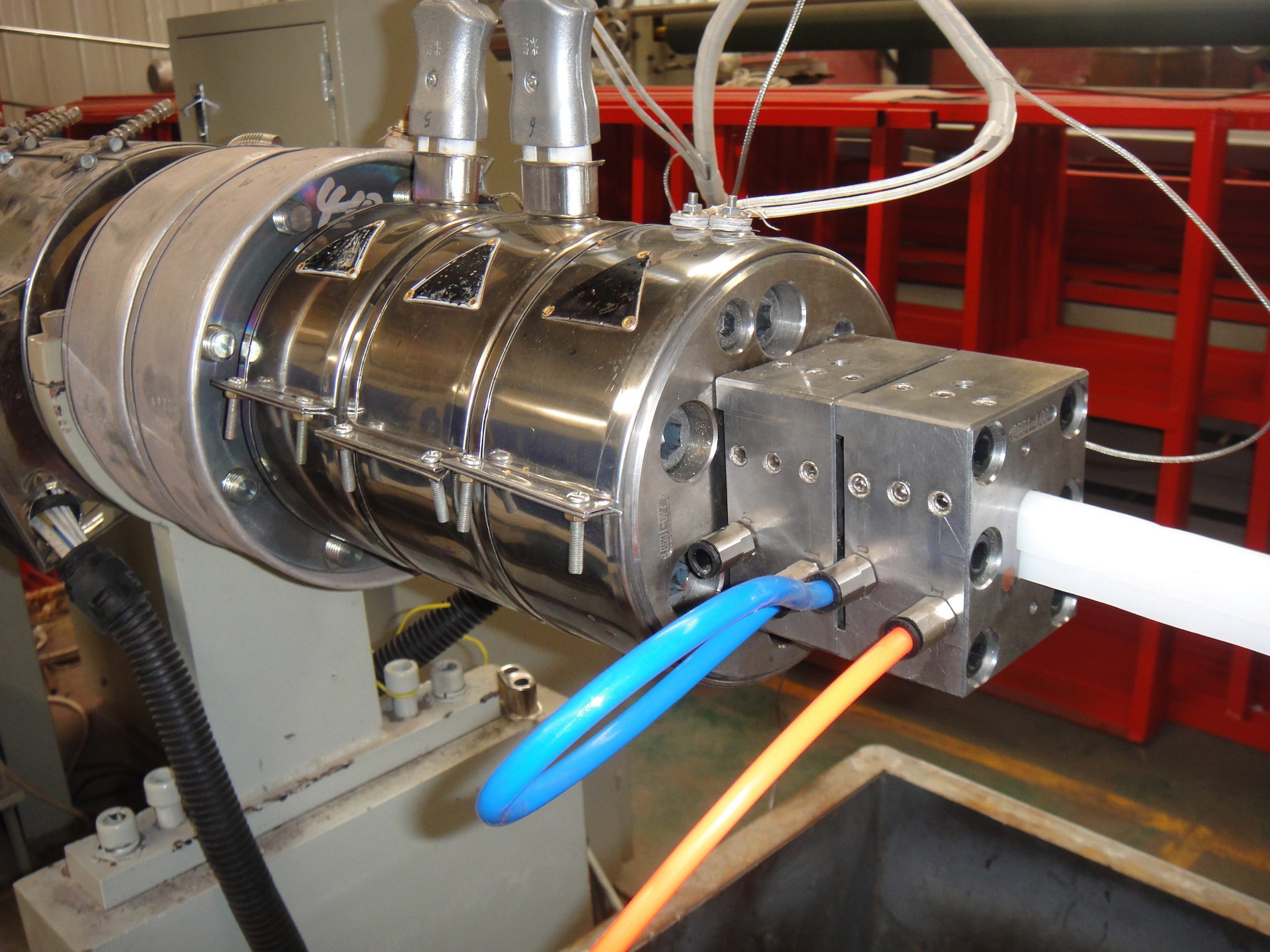

Ingxenye yokugcina edingekayo ye-plastic extrusion yi-die.I-Die isebenza njengesikhunta sepulasitiki-eplastikini ye-plastic extrusion, iyafa ivumela ngisho nokugeleza kwepulasitiki encibilikisiwe.Ukufa kufanele kwenziwe ngokwezifiso futhi kungadinga isikhathi sokuhola esengeziwe ngaphambi kokuqala inqubo yokukhiqiza.

Izinqubo Ezikhethekile Zokukhipha Ipulasitiki

Izinhlelo zokusebenza eziningi zibiza izinqubo ezikhethekile zokukhishwa ukuze kutholwe imiphumela eyanele noma kusheshiswe inqubo yokukhiqiza.Izinqubo ze-extrusion ezikhethekile ezijwayelekile zihlanganisa:

●I-extrusion yefilimu eshaywayo:Isetshenziselwa ukwenza imikhiqizo yefilimu yepulasitiki efana negrosa nezikhwama zokugcina ukudla I-dies kule nqubo ifaka umklamo oqondile, oyisilinda odonsela ipulasitiki encibilikisiwe phezulu njengoba ibumba futhi ipholisa.

●I-Co-extrusion:Izendlalelo eziningana zikhishwa ngesikhathi esisodwa.Ama-extruder amabili noma ngaphezulu anikeza izinhlobo ezahlukene zepulasitiki ekhanda elilodwa le-extrusion.

●Over jacketing:I-Extrusion isetshenziselwa ukumboza into ngepulasitiki evikelayo.Intambo yangaphandle kanye nejakhethi yekhebula kuwuhlelo oluvame kakhulu lwe-overjacketing.

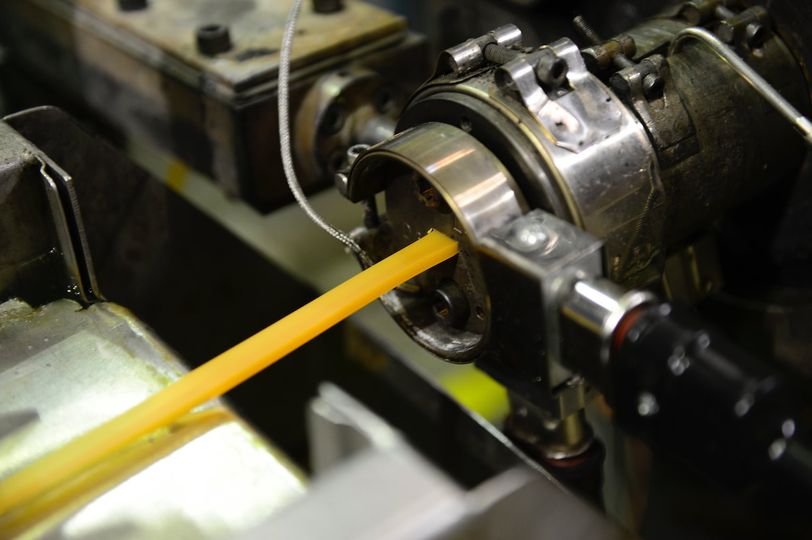

●I-extrusion ye-tubing:Ngokufanayo extrusion bendabuko, ngaphandle die kuhlanganisa izikhonkwane ingaphakathi noma mandrels lula ukukhiqizwa eyize plastic materials.

Inqubo Eyisisekelo Ye-Plastic Extrusion

Inqubo ye-plastic extrusion iqala ngokufakwa kwe-resin eluhlaza ku-hopper ye-extruder.Uma i-resin ingenazo izithasiselo ezidingekayo zohlelo oluthile (njengama-UV inhibitors, ama-anti-oxidant, noma ama-colorants), bese zengezwa ku-hopper.Uma isisendaweni, i-resin ivamise ukuphakelwa amandla adonsela phansi ngomphimbo wokuphakela we-hopper phansi emgqonyeni we-extruder.Ngaphakathi komgqomo kunesikulufu eside, esiphendukayo esiphakela inhlaka phambili emgqonyeni ibheke kufa.

Njengoba i-resin ihamba phakathi komgqomo, iba ngaphansi kwamazinga okushisa aphakeme kakhulu ize iqale ukuncibilika.Kuye ngohlobo lwe-thermoplastic, izinga lokushisa lomgqomo lingahluka phakathi kuka-400 no-530 degrees Fahrenheit.Ama-extruder amaningi anomphongolo okhuphuka kancane kancane ekushiseni ukusuka ekugcineni kokulayisha kuya epayipini lokuphakela ukuze likwazi ukuncibilika kancane kancane futhi kuncishiswe amathuba okuwohloka kwepulasitiki.

Uma ipulasitiki encibilikisiwe ifika ekugcineni komgqomo, iphoqelelwa ngephakethe lesikrini futhi ifakwe epayipini lokuphakelayo eliholela ekufeni.Isikrini, esiqiniswe ipuleti le-breaker ngenxa yezingcindezi eziphezulu emgqonyeni, sisebenzela ukususa ukungcola okungenzeka kube khona epulasitiki encibilikisiwe.I-porosity yesikrini, inombolo yezikrini, nezinye izici zingashintshwa kuze kube yilapho ukuncibilika okufanayo kwenzeka ngenxa yenani elilungile lokucindezela emuva.

Uma isisepayipini lokuphakelayo, insimbi encibilikisiwe ifakwa embotsheni yokufa, lapho ipholisa khona futhi iqine.Ukuze kusheshiswe inqubo yokupholisa, ipulasitiki esanda kwakhiwa ithola ukugeza kwamanzi okuvalekile.Endabeni ye-extrusions ye-plastic sheeting, imiqulu yokupholisa ithatha indawo yokugeza amanzi.

Isikhathi sokuthumela: Oct-25-2021